|

|

The emerging process of 3-D printing, which uses computer-created

digital models to create real-world objects, has produced everything

from toys to jewelry to food.

Soon, however, 3-D printers may be spitting out something far more complex, and controversial: human organs.

For years now, medical

researchers have been reproducing human cells in laboratories by hand to

create blood vessels, urine tubes, skin tissue and other living body

parts. But engineering full organs, with their complicated cell

structures, is much more difficult.

Enter 3-D printers, which

because of their precise process can reproduce the vascular systems

required to make organs viable. Scientists are already using the

machines to print tiny strips of organ tissue. And while printing whole

human organs for surgical transplants is still years away, the

technology is rapidly developing.

"The mechanical process isn't all that complicated. The tricky part is the materials, which are biological in nature," said Mike Titsch, editor-in-chief of 3D Printer World,

which covers the industry. "It isn't like 3-D printing plastic or

metal. Plastic doesn't die if you leave it sitting on an open-air shelf

at room temperature for too long."

Lawrence Bonassar, a professor of biomedical engineering at Cornell

University, with an artificial ear made via 3-D printing and injectable

molds.

The idea of printing a

human kidney or liver in a lab may seem incomprehensible, even creepy.

But to many scientists in the field, bioprinting holds great promise.

Authentic printed organs could be used for drug or vaccine testing,

freeing researchers from less accurate methods such as tests on animals

or on synthetic models.

Then there's the hope

that 3-D printers could someday produce much-needed organs for

transplants. Americans are living longer, and as we get deeper into old

age our organs are failing more. Some 18 people die in the United States each day waiting in vain for transplants because of a shortage of donated organs -- a problem that Anthony Atala, director of the Wake Forest Institute for Regenerative Medicine and a pioneer in bioprinting, calls "a major health crisis."

An 'exciting new area of medicine'

Bioprinting works like

this: Scientists harvest human cells from biopsies or stem cells, then

allow them to multiply in a petri dish. The resulting mixture, a sort of

biological ink, is fed into a 3-D printer, which is programmed to

arrange different cell types, along with other materials, into a precise

three-dimensional shape. Doctors hope that when placed in the body,

these 3-D-printed cells will integrate with existing tissues.

The process already is seeing some success. Last year a 2-year-old girl in Illinois, born without a trachea, received a windpipe built with her own stem cells. The U.S. government has funded a university-led "body on a chip" project

that prints tissue samples that mimic the functions of the heart,

liver, lungs and other organs. The samples are placed on a microchip and

connected with a blood substitute to keep the cells alive, allowing

doctors to test specific treatments and monitor their effectiveness.

"This is an exciting new

area of medicine. It has the potential for being a very important

breakthrough," said Dr. Jorge Rakela, a gastroenterologist at the Mayo

Clinic in Phoenix and a member of the American Liver Foundation's medical advisory committee.

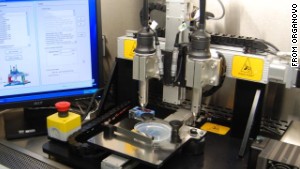

One of Organovo's engineers oversees the construction of a vascular tissue construct on a NovoGen MMX bioprinter.

"Three-D printing allows

you to be closer to what is happening in real life, where you have

multiple layers of cells," he said. With current 2-D models, "if you

grow more than one or two layers, the cells at the bottom suffocate from

lack of oxygen."

To accelerate the development of bioprinted organs, a Virginia foundation that supports regenerative medicine research announced in December it will award a $1 million prize for the first organization to print a fully functioning liver.

One early contender for the prize is Organovo, a California start-up

that has been a leader in bioprinting human body parts for commercial

purposes. Using cells from donated tissue or stem cells, Organovo is

developing what it hopes will be authentic models of human organs,

primarily livers, for drug testing.

The company has printed

strips of human liver tissue in its labs, although they are still very

small: four by four by one millimeter, or about one-fourth the size of a

dime. Each strip takes about 45 minutes to print, and it takes another

two days for the cells to grow and mature, said Organovo CEO Keith

Murphy. The models can then survive for about 40 days.

Organovo has also built models of human kidneys, bone, cartilage, muscle, blood vessels and lung tissue, he said.

"Basically what it

allows you to do is build tissue the way you assemble something with

Legos," Murphy said. "So you can put the right cells in the right

places. You can't just pour them into a mold."

Ethical concerns

Not everyone is comfortable with this bold new future of lab-built body parts, however.

A research director at

Gartner Inc., the information-technology research and advisory firm,

believes 3-D bioprinting is advancing so quickly that it will spark a

major ethical debate by 2016.

A 3-D printer at Cornell University produces an artificial ear.

"Three-D bioprinting

facilities with the ability to print human organs and tissue will

advance far faster than general understanding and acceptance of the

ramifications of this technology," Pete Basiliere said in a recent report.

"These initiatives are

well-intentioned, but raise a number of questions that remain

unanswered," Basiliere added. "What happens when complex 'enhanced'

organs involving nonhuman cells are made? Who will control the ability

to produce them? Who will ensure the quality of the resulting organs?"

Bioprinted organs are also likely to be expensive, which could put them out of reach of all but the wealthiest patients.

Murphy said Organovo

only uses human cells in creating tissues, and doesn't see any ethical

problems with what his company is doing.

"People used to worry

about doing research on cadavers ... and that dissipated very quickly,"

he said. "We don't think there's any controversy if you're producing

good data and helping people with health conditions."

Most experts, including Wake Forest's Atala,

don't think we'll see complex 3-D-printed organs, suitable for

transplants, for years if not decades. Instead, they believe the next

step will be printing strips of tissue, or patches, that could be used

to repair livers and other damaged organs.

Organovo's NovoGen MMX bioprinter is small enough to fit into a cabinet.

"We are very eager to

put pieces of tissue to work for surgical transplants," said Organovo's

Murphy, who hopes his company will be ready to begin clinical trials

within five years.

Of course, any use of

3-D-printed tissue in surgical procedures would require approval by the

U.S. Food and Drug Administration. That review process could take up to a

decade.

By then, the notion of a

surgeon putting a 3-D-printed kidney into a patient may not seem so

bizarre. Then again, this swiftly evolving technology may create new

moral conundrums.

"The ethical questions

are bound to be the same concerns we have seen in the past. Many major

medical breakthroughs have suffered moral resistance, from organ

transplants to stem cells," said Titsch of 3D Printer World.

"Will only the rich be able to afford it? Are we playing God? In the end, saving lives tends to trump all objections."

No hay comentarios:

Publicar un comentario